Li-S Energy Limited commences trading today on the ASX after raising $34m via an IPO of 40m shares at $0.85 (Offer Price). The market capitalisation at the Offer Price is $544m. Post the IPO PPK Group Limited is the largest shareholder (45.43%) with Deakin University (Deakin) and BNNT Technology owning 13.02% and 4.69% respectively. Incoming shareholders hold just over 6% of Li-S Energy.

Following the IPO and earlier funding rounds, Li-S Energy is exceptionally well capitalised to pursue its commercial and R&D activities with pro forma cash balance of $52.9m. Of this, $29m is earmarked for project expenditure with working capital of ~$16.5m to fund potential expansion and/or acceleration of existing projects, commencement of new development projects and the pursuit and engagement in revenue generating opportunities through Original Equipment Manufacturer (OEM) collaboration and other partnerships.

Li-S Energy’s Market Opportunity

The global rechargeable battery industry is attempting to scale rapidly to accommodate demand growth from EV manufacturers, e-mobility, grid storage, consumer portable devices, aviation, defence and public safety sectors. Lithium-ion battery chemistry currently dominates this industry as it is relatively mature and proven, with large manufacturing facilities currently in place.

However, emerging industries are demanding higher energy capacity, lower weight, faster charging, safer performance and lower cost batteries that commercial lithium-ion chemistries have yet to deliver. In particular, analysts have identified that in the rapidly emerging EV industry, current battery cost (at up to 30% of total vehicle cost), limited range and slow charging are key factors limiting EV adoption globally.

In short, the next generation of battery technology is required to meet expected demand, drive mass adoption and innovation. Li-S Energy is working to meet this need and has made unique technological advancements which offer the potential to produce, in commercial quantities, an advanced lithium-sulphur battery providing vastly improved operating performance.

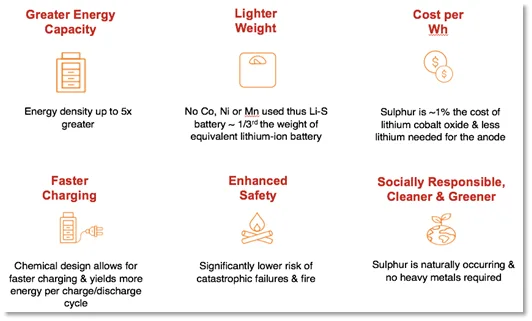

Advantages of Lithium-Sulphur vs Lithium-Ion Batteries

For decades, scientists have known that using lithium and sulphur electrodes in a battery presented one of the best opportunities to create a high-performance battery.

CEO Dr Lee Finniear commented:

“The success of the IPO is testament to the market’s understanding of, and enthusiasm for, the breakthroughs we have made to render possible the commercial viability of lithium-sulphur batteries. Ours is a genuine Australian technology success story with global application and the realistic potential to allow EVs to drive further, drones to fly longer and mobile devices to last for days instead of hours.

We continue to make strong technical progress. Our initial testing on a single layer BNNT protected pouch cell as detailed in our prospectus has reached 900 charge/discharge cycles while retaining more than 60% of its initial specific capacity. We are now scaling our technology with the construction and testing of multi-layer lithium-sulphur cells.

We are also very excited about Li-Nanomesh, the new nano-composite we created to reduce dendrite formation on lithium anodes. Initial testing by Deakin University shows virtually no dendrite formation after 1,000 charge cycles. Importantly, we believe Li-Nanomesh could be an excellent solution for other battery types including lithium metal batteries that suffer similar dendrite problems. This could significantly expand our addressable market, and we are now preparing to test this extended use-case.

We are in an enviable financial position to pursue commercialisation of our technology into a global market looking for alternatives to lithium-ion batteries – a mature technology that is essentially ‘maxed out’ in terms of opportunities to materially improve its operating performance.”

The key comparative advantages of conventional lithium-sulphur over lithium-ion batteries are summarised below:

Figure 1: Key comparative advantages of conventional lithium-sulphur batteries over lithium-ion batteries

Whilst the advantages of lithium sulphur batteries are well known, they tend to fail quickly, often in less than 100 charge/discharge cycles. As a result, until now, they have simply not been practical for most mainstream battery applications.

Li-S Energy’s Technology Solution

Li-S Energy has made two key breakthroughs to dramatically improve the cycle life of lithium-sulphur batteries, approaching that of everyday consumer-grade lithium-ion batteries. The opportunity to commercially supply affordable, high performance lithium-sulphur batteries offers the potential to drive adoption in multiple markets, to create EVs that drive further, drones that fly longer and mobile devices that last for days instead of hours.

Firstly, in conjunction with Deakin we have used boron nitride nanotubes (BNNTs) as a nano-insulator, adding it to the battery’s cathode to help stabilise it and protect it during charge and discharge. Specifically, the BNNTs within the battery construction act to allow lithium ions to flow, while reducing the movement of lithium polysulfides. This assists in sulphur retention as active material in the cathode, helping to maintain battery capacity during charge/discharge.

Secondly we have added our new nano-composite, Li-Nanomesh to the battery’s anode to mitigate dendrite formation. Dendrites are ‘spiky’ or ‘mossy’ lithium structures that can form on the anode during repeated charge cycles causing loss of capacity, short-circuits and early failure.

In simple terms, initial testing has shown that the application of these two technologies is able to retain the high energy capacity of a lithium-sulphur battery while also substantially extending its cycle life.

Figure 2: Li-S Energy Battery componentry with BNNT and Li-Nanomesh

Li-S Energy has lodged two key provisional patents covering the innovative function of BNNTs and Li-Nanomesh within the construction and chemistry of the resulting lithium-sulphur battery (Li-S Energy Battery).

BNNT Technology Breakthrough

BNNT is an advanced nano-material which has a number of unique properties including being an electrical insulator, being able to withstand temperatures over 900°C in untreated air without degradation and being seven times more thermally conductive than copper. Certain of its properties are critical to the performance of the Li-S Energy Battery.

Historically, BNNTs have been very difficult to make in high purities and high volume. Due to both high cost and modest supply, BNNTs have traditionally been overlooked in new product development.

Critically, the barriers of BNNT price, purity and volume availability are now coming down. In 2020, BNNTTL, who was at the time a substantial shareholder in Li-S Energy, successfully commissioned a commercial scale BNNT production facility in Geelong, Victoria utilising Deakin University’s patented BNNT manufacturing technology and expertise.

BNNTTL has a 20 year worldwide exclusive right to use Deakin’s relevant intellectual property (IP) and can now produce and supply large quantities of high purity BNNTs. Li-S Energy has secured a supply agreement with BNNTTL to provide commercial quantities of BNNTs as well as an exclusive distribution agreement to distribute BNNTs for use in lithium-sulphur batteries, to the global battery industry.

Commercial Strategy

Li-S Energy’s battery research is well advanced and our R&D program is designed to provide a path to market. The Company is not focused on becoming a large-scale battery manufacturer in its own right, instead we intend to licence our IP and sell BNNT and Li-Nanomesh materials to battery manufacturers enabling them to mass produce Li-S Energy Batteries.

Our intention is to invest in the scale up of our development and production team, design and implement a pilot battery production facility and, in collaboration with product manufacturers, demonstrate the performance benefits of Li-S Energy Batteries for a range of global products.

The R&D program has the following five primary goals:

- Further optimise lithium-sulphur technology

- Produce Li-S Energy Battery cells in formats that meet the requirements of product manufacturers in key industries

- Build a pilot production facility, produce Li-S Energy Battery cells and prove their benefits in commercial products with commercial partners

- Develop IP on how existing lithium-ion battery manufacturing plants can be adapted to produce Li-S Energy Batteries.

- Licence Li-S Energy IP to battery manufacturers to produce Li-S Energy Batteries and enter into supply agreements to sell BNNT and Li-Nanomesh in production volumes.

Recent Progress

Since the replacement prospectus was issued on 29 July 2021 (Prospectus), the Company has made substantial progress in a number of areas:

- Initial testing on the single layer BNNT protected pouch cell reported in the Prospectus has been continuing, reaching 900 charge/discharge cycles at greater than 60% retained capacity. We are now focused on building and testing a range of single layer pouch cells with different sulphur mass loadings and BNNT loadings to optimise performance and cost.

- We have also started building multi-layer lithium-sulphur pouch cells. This is a significant step toward scaling our technology. We will initially build and test 4-layer cells, and we intend to scale to 10-layer cells and above as the testing validates each step of the scaling process.

- Dendrite growth prevention on lithium anodes is of vital importance not just for lithium-sulphur batteries, but for all batteries that use a metal anode, including lithium-metal batteries. Li-S Energy has developed, and owns the IP for, a unique Li-Nanomesh composite material. Initial testing demonstrates it can effectively mitigate dendrite formation.

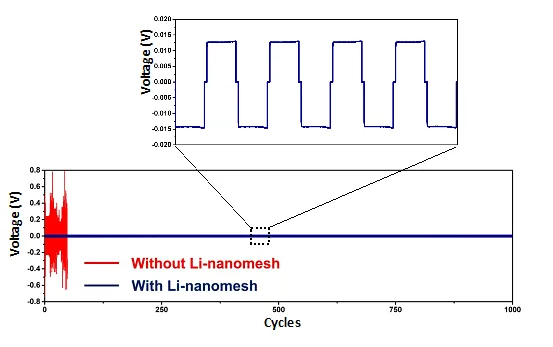

Li-S tested several identical lithium symmetric half cells with and without Li-Nanomesh. In this initial testing the cell without Li-Nanomesh formed dendrites and failed after 45 cycles. The cells with Li-Nanomesh completed 1000 cycles with no indication of dendrite growth. These initial results are highly encouraging. We therefore plan to accelerate the project to test Li-Nanomesh at higher charge/discharge rates and current densities. We will also test Li-Nanomesh on full lithium-sulphur and lithium-metal pouch cells.

Figure3 – Li-Nanomesh testing Voltage Hysteresis Graph – higher voltage denotes dendrite formation

Dr Lee Finniear finished with.

Scaling our team, talent pool and facilities continues to be vital to our ongoing progress. We have expanded our team by engaging with a number of talented electrochemists and research technicians.

We are currently engaging with an internationally renowned European battery research institution to leverage their lithium anode cell construction and production expertise.

We are also in the process of fitting out the new laboratory and test areas in the Deakin Manufactures building. This will expand our R&D and cell testing capacity. We are in discussions to acquire additional dedicated space for our pilot production facilities.