The escalating impacts of climate change pose significant threats to Australia’s pharmaceutical sector, emphasising the urgent need for robust and adaptive strategies.

Leveraging cutting-edge technology such as satellite data, advanced analytics, and machine learning models, the industry can access real-time weather and climate information.

Pharma companies equipped with the weather resilience tools provided by Tomorrow.io are able to anticipate and mitigate climate-related disruptions effectively.

By implementing infrastructure risk assessments, operational adaptations, and proactive emergency planning, these companies are not only protecting their supply chains but are also securing their manufacturing processes against the increasing unpredictability of global weather patterns.

Through detailed analysis and strategic application of weather intelligence tools, the sector aims to safeguard and future-proof its operations, maintaining reliability and safety in healthcare delivery amidst a changing climate.

Infrastructure Risk Assessment

Climate change poses major challenges to pharmaceutical facilities in Australia, and our detailed infrastructure risk assessment shows the industrial sector’s growing vulnerability to extreme weather events.

Facility Location Analysis

Our assessment of facility locations takes into account multiple climate-related factors that affect pharmaceutical operations. The industrial sector needs stable climate conditions to run complex supply chains effectively.

Flooding, landslides, and storm damage to roads and infrastructure cause major disruptions. Hurricane Maria’s impact on Puerto Rico proved this point – more than 500 medical product facilities were affected. This shows why location-based risk assessment matters so much.

Climate Impact Modelling

We use advanced climate impact modeling to predict and prepare for potential risks. Our modeling approach covers:

- Temperature variations affecting manufacturing processes

- Seasonal rainfall patterns and flood risks

- Drought impacts on water-intensive operations

- Storm and wildfire danger assessments

Physical risks can be determined from past and current natural hazards, climate change projections, and relevant climate variables. Climate change risk management keeps evolving as extreme events increase and risk management culture improves.

Resource Vulnerability Mapping

Our resource vulnerability mapping spots critical dependencies and weak points in pharmaceutical operations.

Data shows that droughts will hurt industrial sector companies that rely on water-intensive manufacturing. Rising average temperatures reduce worker productivity, disrupt industrial cooling, and drive up air conditioning costs.

We’ve taken an all-encompassing approach that looks at manufacturing plants, packaging facilities, and warehouses, along with regions that supply important production inputs.

This mapping helps us grasp both direct effects on manufacturing and business operations, including supply chains, and indirect effects from government and regulatory policies.

Operational Adaptation Measures

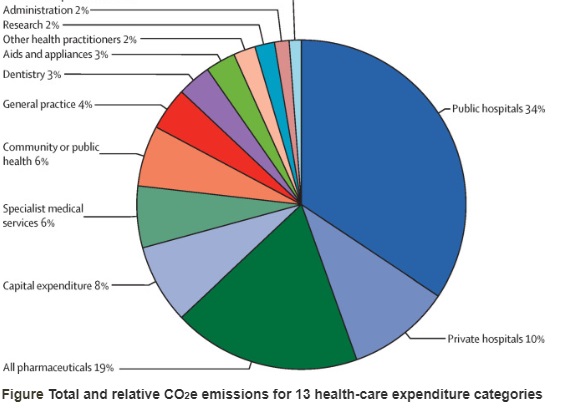

We build resilient pharmaceutical operations by implementing reliable operational adaptation measures. Healthcare contributes a lot to environmental effects and is responsible for 4-5% of global greenhouse gas emissions.

Energy Efficiency Solutions

Energy efficiency in pharmaceutical manufacturing goes beyond cost reduction. It’s a vital strategy that reduces our carbon footprint. Our analysis reveals that 70-80% of the carbon footprint resides in the manufacturing process. We are implementing:

- Advanced HVAC systems and energy-saving lighting

- Flow chemistry approaches replacing traditional stainless steel vessels

- Live energy monitoring systems

- Automated control systems for optimized usage

Water Conservation Strategies

This is due to many of the major constraints which is scarcity of water and other liquid resources. This has been projected to decline within the next ten years to about 40% short of fresh water supply.

The implementation of our detailed water stewardship programmes takes place in all of our facilities. The goal is to have excellent water stewardship by 2025 and also the overall utilisation of water at 20% less in 2030.

Our water supply chain constitutes 95% of water usage. This makes supplier participation as critical for attaining the right conservation objectives.

Waste Management Systems

The pharmaceutical sector requires innovative management strategies in waste management in order to minimize the impacts on the environment.

Health care sector in Australia contributes to about 35,800,000 tonnes CO2 equivalent emission per year. Selective sorting strategies for wastewater management are still being explored at the advanced level here.

Live monitoring systems help Australian’s map resource usage dynamically. This helps us identify ways to improve and spot potential risks effectively.

Emergency Response Planning

Our pharmaceutical operations need strong emergency preparedness strategies to handle climate-related disruptions. Data reveals that approximately 6,000 people ask about pharmaceutical products each month, which shows why we need reliable emergency protocols.

Crisis Management Protocols

The numbers tell us that only 49% of US companies have formal crisis communications plans ready for unexpected events. Our improved protocols now have:

- Regular updates to hospital and community pharmacy disaster plans

- Mandatory training on disaster preparation

- Climate impact assessment in emergency responses

- Specialized toolkits for natural disaster preparedness

Business Continuity Planning

The goal is to ensure that supply chains for medicine processing are not disrupted anywhere, anytime. COVID-19 tested most continuity plans severely because they focused on specific regions instead of global disruptions.

New strategies now cover both regional and worldwide scenarios, especially since healthcare systems add about 4.4% to global emissions.

Stakeholder Communication

Clear communication during crises helps build trust and optimize operations. Our multi-channel system handles approximately 70,000 questions yearly. The strategy now includes:

- AI-supported call center systems

- ‘Direct to Patients’ systems for emergency medication access

- Cross-departmental task forces for coordinated response

Our 5-year-old crisis communication teams and regular training drills have significantly enhanced preparedness. This is especially important as healthcare systems lag behind other service sectors in reducing carbon emissions.

Integrating Tomorrow.io’s weather API now equips us with the tools to predict and respond to climate-related emergencies effectively while maintaining essential pharmaceutical services.

Future-Proofing Investments

The pharmaceutical industry’s future depends on climate-resilient technologies and capabilities. Our member companies show their dedication to sustainable transformation clearly. 70% of our member companies have raised their climate action ambitions.

Sustainable Technology Integration

A transformation in technology adoption shows more than 70% of our members conduct climate scenario analysis. Our investment priorities include:

- Digital supply chain optimisation platforms

- Advanced emissions monitoring systems

- Renewable energy infrastructure

- Smart water management solutions

60% have set net-zero commitments, which proves our industry’s path toward a sustainable future.

Research and Development Focus

Climate resilience drives our R&D initiatives. Data reveals that every dollar invested in adaptation and resilience measures can yield £1.57–15 in financial benefits.

Green chemistry research takes priority, and companies like Bayer lead efforts to improve Active Pharmaceutical Ingredients’ (API) ecological footprint.

Most companies address scope 3 emissions through ambitious targets with their suppliers. Novo Nordisk exemplifies this by asking all direct suppliers (approximately 60,000) to use renewable power by 2030.

Workforce Development Programmes

Climate change affects our workforce because it is a commitment to embedding climate resilience across all its operations.

A recent study indicates that 70 percent of millennials would like to work for a socially and environmentally conscious organisation. In response to this, we design and implement a sophisticated training curve that educates our employees on how to support sustainability efforts.

The sustainable bond market also plays a crucial role, with 19% of capital directed toward climate resilience activities. This comprehensive approach strengthens both technological and human capacities to address climate challenges.

Integrating Tomorrow.io’s weather resilience solutions fosters better industry collaboration. More than 60% of companies have set short-term emission reduction targets, and these coordinated efforts help future-proof our operations against climate impacts while maintaining our essential role in Australia’s healthcare system.

Conclusion

Tomorrow.io has developed innovative weather solutions for the pharma industry which has assisted the Australia’s pharma industry to deal with climate issues in the industry more efficiently.

It also gives the pharma company a holistic approach to help in improving infrastructure analysis, operations change and emergency preparedness.

However, the assessments made within this article suggest that there is still much work to be done to achieve all of these goals; the current footing is solid.

Of the member companies, 70% have upped their climate goals while 60% have pledged for net-zero. Such achievements prove the industry’s stance on environmental sustainability while containing the key health services provision.

Currently, through the integrated application of complicated technologies, adequate and rapid responding emergency management systems, as well as proactive and innovative investments, the pharmaceutical industry should not have many problems when addressing climate disruptions.

Our water usage reduction target is to achieve a 20% cut by 2030; the manufacturing-related 70-80% carbon footprint is targeted to be achieved through energy efficiency.

Several Australian pharmaceutical firms are taking the lead with the Tomorrow.io to show that being friendly to the environment and delivering efficiency do not have to be incompatible.