Intel CEO, Pat Gelsinger says his effort to reclaim chip technology leadership is on track.

Intel on Thursday showed off a silicon wafer studded with chips built with a manufacturing process slated to arrive in 2025, a signal meant to reassure customers that the company’s years of chipmaking struggles are behind it.

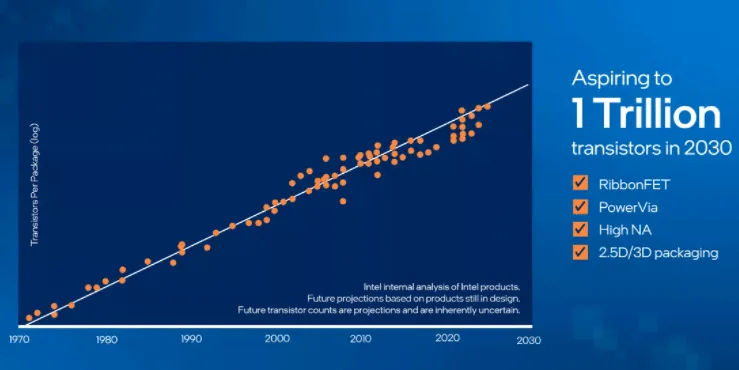

Intel is looking to dramatically accelerate manufacturing progress to meet its 2025 goal of regaining the chip performance lead it lost to Taiwan Semiconductor Manufacturing Co. (TSMC) and Samsung.

If successful, it will mean PC chips progress faster after half a decade of lackluster performance improvements. And that could mean Intel becomes more relevant to your digital life by building chips inside your car, phone, and gaming PC graphics card.

“We remain on or ahead of schedule against the timelines that we laid out,” Chief Executive Pat Gelsinger said of the company’s plan to improve manufacturing processes.

He showed off a brilliant slice of memory chips built with the company’s upcoming Intel 18A process, which overhauls the transistors at the heart of the chip’s circuitry and how power is delivered to them.

At the heart of the effort are five new manufacturing processes over four years: Intel 7 in 2021 with Alder Lake chips now powering PCs, Intel 4 in 2022, Intel 3 in 2023, Intel 20A in early 2024, and Intel 18A in late 2024, although the delay between production availability and product delivery means the 18A chips won’t arrive until 2025. Showing the wafer is a “proof point” that Intel is on track, Gelsinger said.

Gelsinger, a chip engineer who returned to Intel a year ago, brings tech credibility to the CEO role, but it will be difficult for the company to get its way back.

When a chipmaker lags behind the forefront, as IBM and GlobalFoundries have done in recent years, it becomes more difficult to justify the colossal investments required to move forward with the new technology.

Gelsinger spoke at Intel’s investor day, where he and other executives sought to convince often sceptical analysts that the company’s massive spending on new chip-making equipment would be worth it.

Embodying Intel’s difficulty is Apple’s decision to eject Intel Core processors from its Macs in favour of its own M series chips built by TSMC. At the same time, AMD has been gaining market share

At the same time, AMD is gaining market share, Nvidia is gaining on gaming and AI, and Amazon is introducing its own server processors.

Intel 20A introduces two major changes to the chip design, RibbonFET and PowerVia, and Intel 18A refines it for better performance. RibbonFET is Intel’s take on a transistor technology known as an All Around Gate, in which the gate that regulates whether the transistor is on or off is wrapped entirely around ribbon-like channels that carry electrical current.

Intel is pressing with another possibility: packaging technology that links several “chiplets” into a more powerful processor.

The Sapphire Lake member of Intel’s Xeon server family coming this year uses a variety of packaging, called EMIB, while the Meteor Lake PC chip coming in 2023 uses another, called Foveros.

Intel’s New PC processors on the way

Intel built its first Meteor Lake prototypes in the final quarter of 2021 with the Intel 4 process and booted them up in PCs, said Ann Kelleher, the executive vice president who leads Intel’s technology development division.

“This is one of the best lead product start-ups we have seen in the last four generations of technology,” Kelleher said. “Over its lifetime, Meteor Lake will ship hundreds of millions of units, offering the clearest demonstration of leadership packaging technologies in high volume.”

Packaging will play a role in future PC processors, including Arrow Lake in 2024, which will incorporate the first chiplets built with Intel 20A. After that comes Lunar Lake, which will use Intel 18A chips. Meteor Lake and Arrow Lake will use a new graphics chip architecture that Intel says will be “a huge step forward”, which is important given that graphics chips today do much more than paint pixels on your screen – for example AI and video image processing.

Kelleher also detailed the many changes to research and manufacturing to head off the catastrophic problems that Intel has faced in recent years. First, improvements are now modular, so a problem with one shouldn’t interfere with the others.

Secondly, Intel is developing plans in case problems arise. And he pays more attention to the advice of chip equipment suppliers such as ASML.